Skins and Stiffener Work Continues

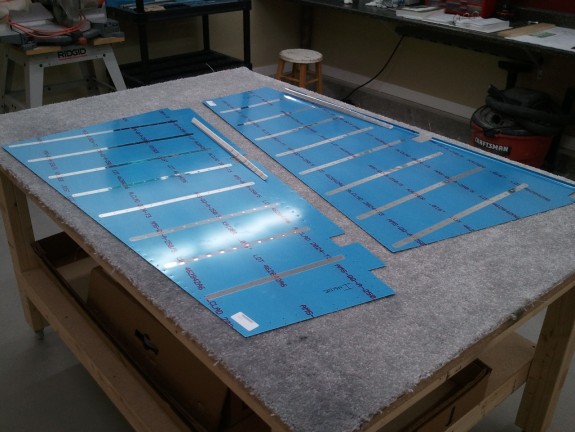

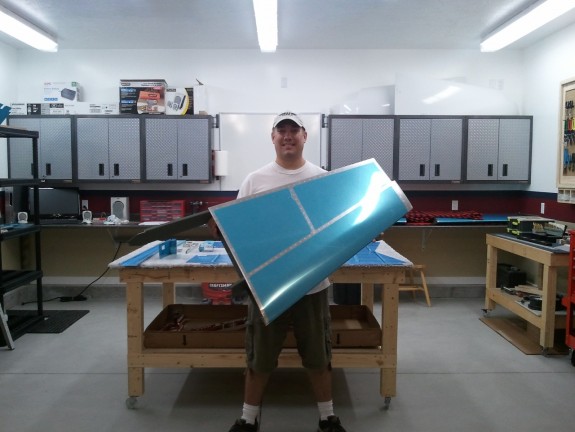

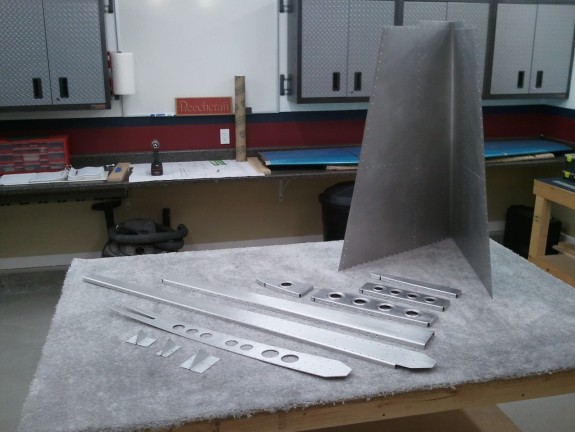

With the Rudder Skins now match drilled, and being that it is Friday, it was time to get some prep work done for tomorrow’s marathon build session. I deburred all the holes in the skins and the stiffeners and went to town on the DRDT-2 dimpling the skins and the stiffeners with my pneumatic squeezer. I then scuffed all the parts and started priming at least the sections of the skins where the stiffeners would interface. The vinyl coating makes a great paint mask. I am still debating if I will prime the inside of the skins elsewhere as that is the furthest part from them CG where extra weight makes a big difference. If anything I can Corrosion X the inside once it is built and painted. Or I can mist the rest of the skins with primer for a little help. We’ll see where it ends up in the coming days.

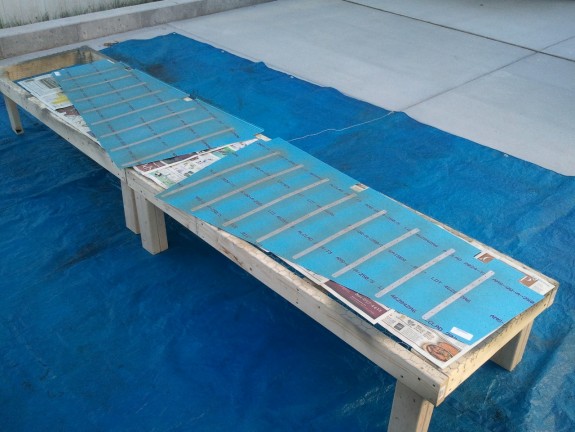

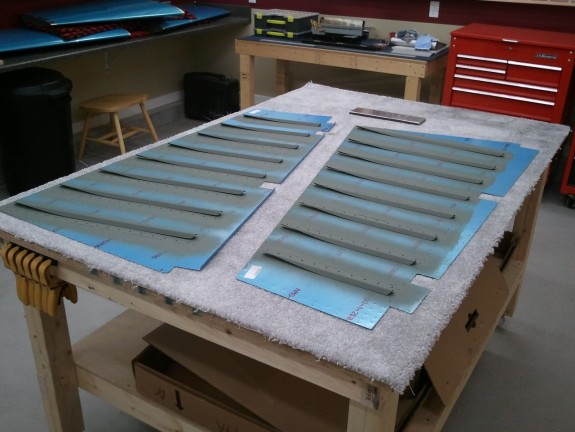

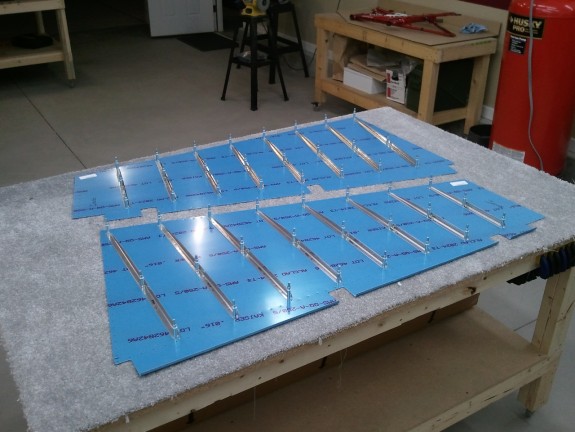

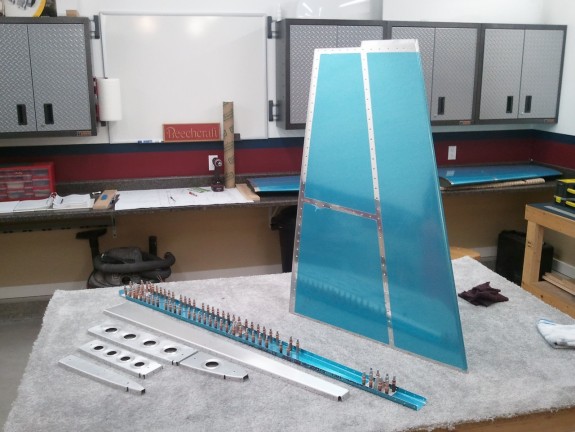

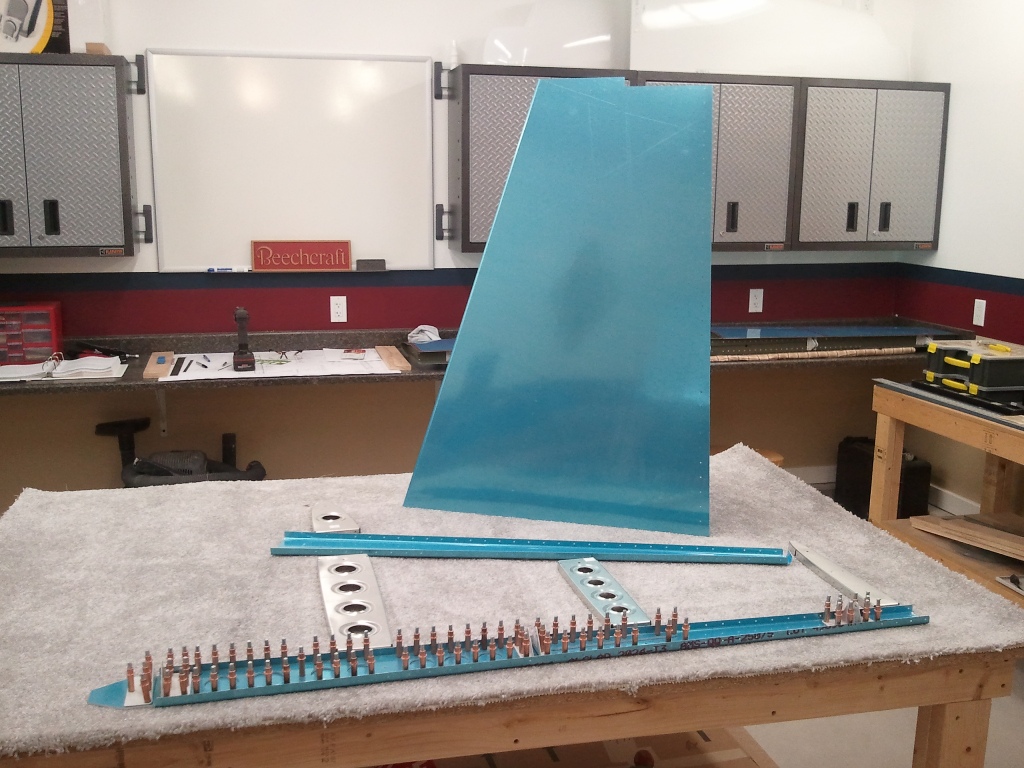

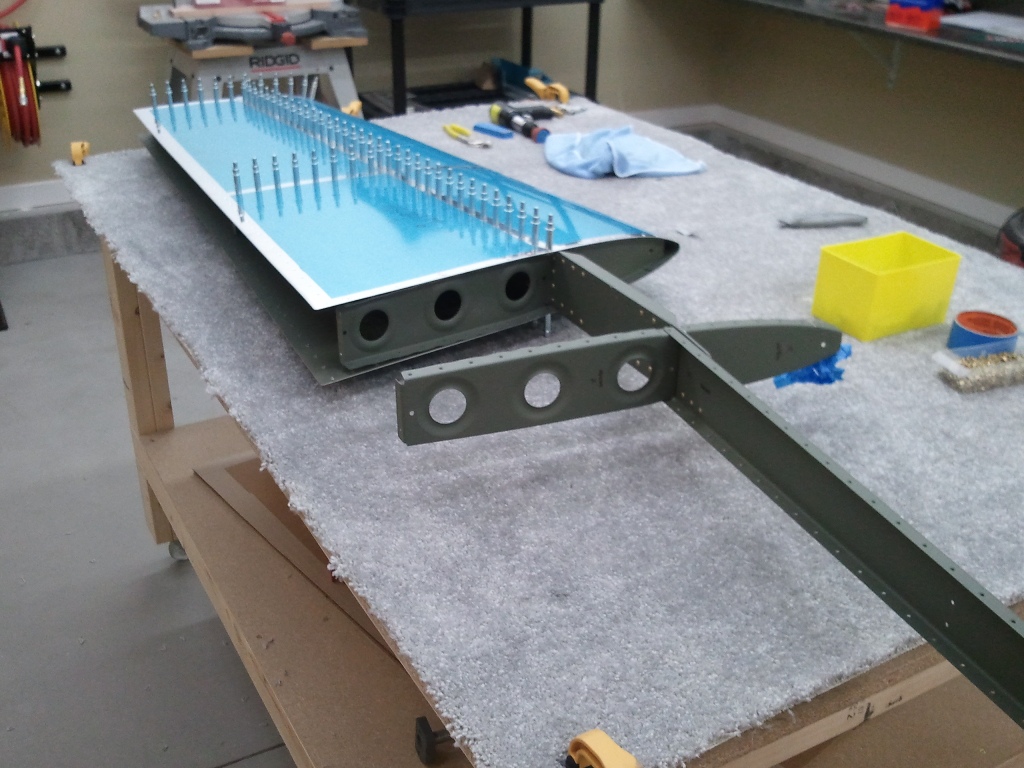

While the primer was drying on the skins, I finished deburring and scuffing the stiffeners and readying them for primer as well. I made up a little standoff for them all out of two sections of cardboard from the inside of the tail kit box. Basically, created two sections of cardboard angle and then notched the bend 18 times each so I could point the insides toward the sky and spray them. Once they were dry, I simply flipped them over and sprayed the backs. Here you can see the stiffeners and skins all set up and ready to be married together forever. I cleaned up the shop some and let them dry.

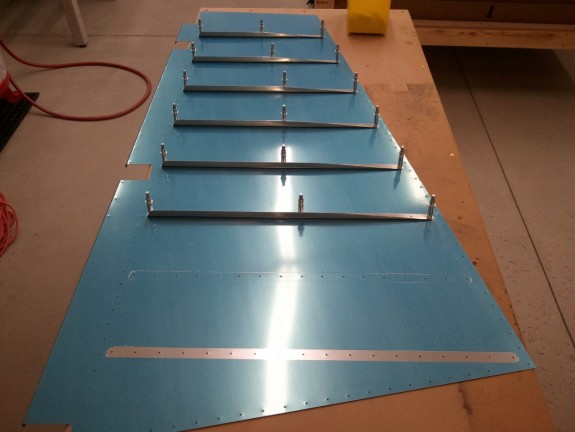

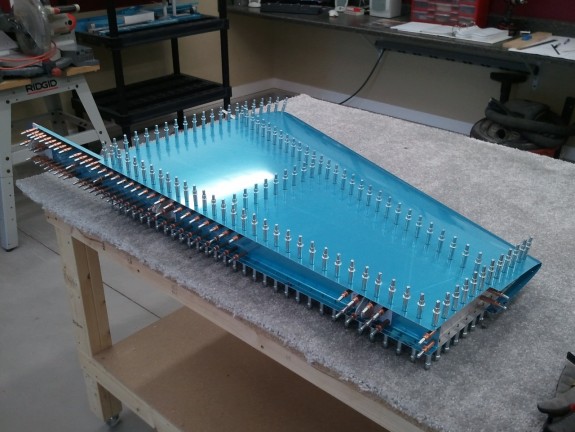

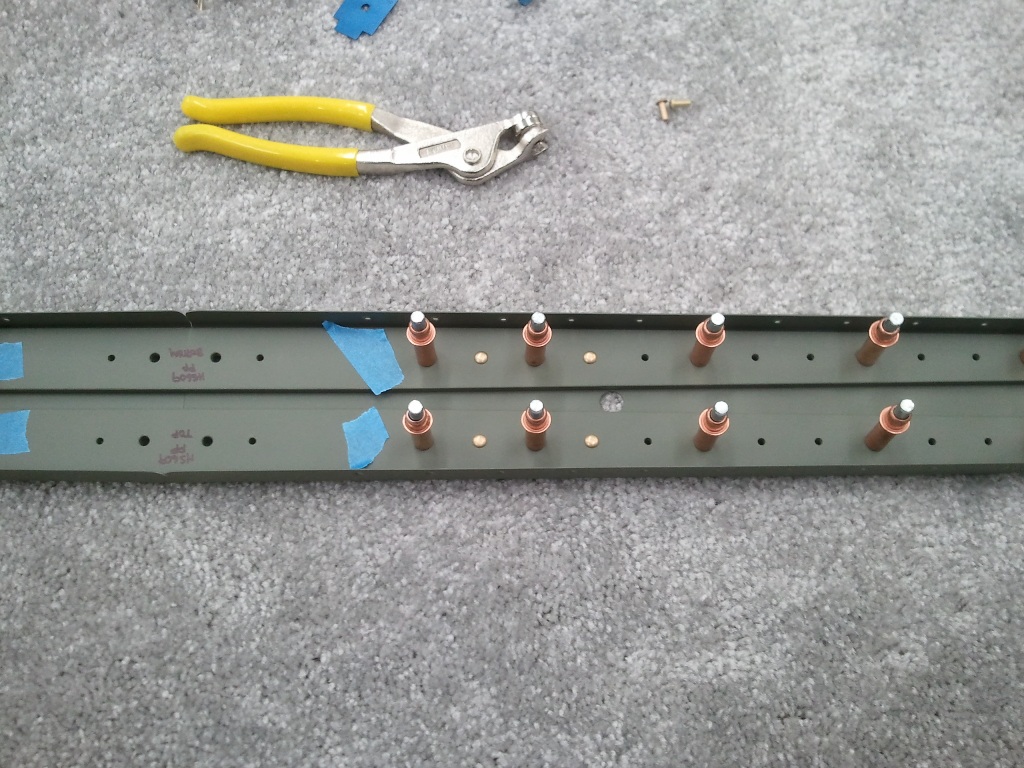

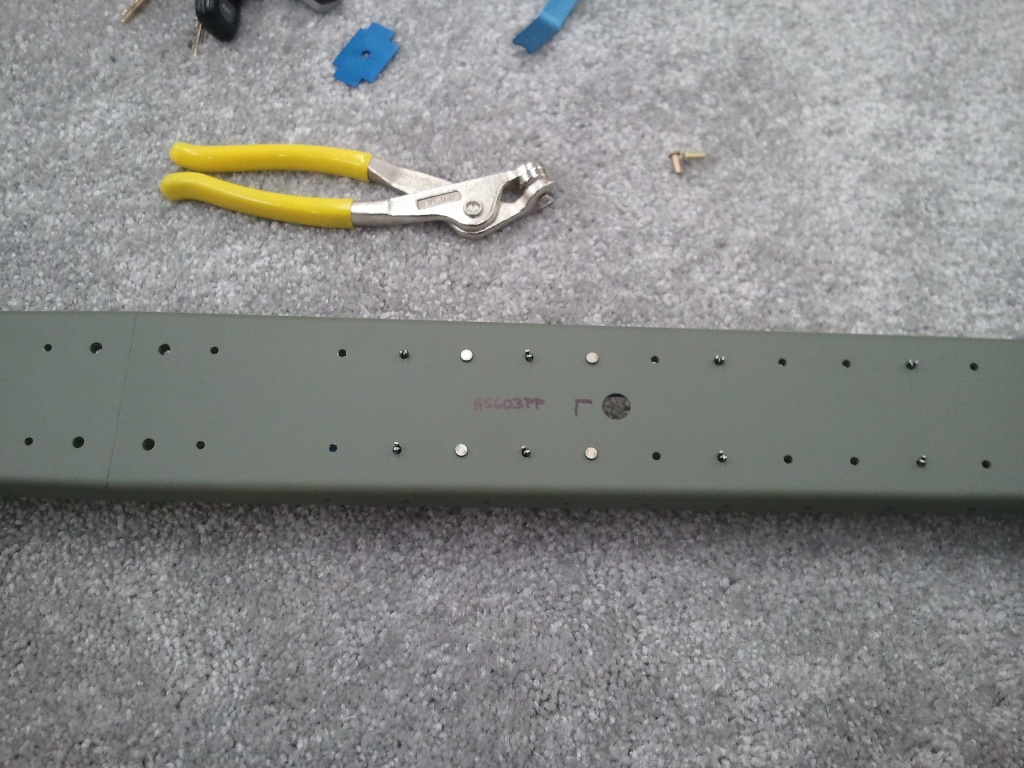

It was late when the primer was dry on the stiffeners. I took the time to take a look at my back rivet set and polish up my back rivet plate some. I felt I needed to polish the face of my back rivet set collar as it has a brass collar rather than Delrin as I have seen elsewhere. I also had to lube it up some. All this prep made anxious to give back riveting a whack and I was not tired. So before finishing up the night, I decided to back rivet one of the skins. Here is the result. I like back riveting…you can get somewhere fast with the right tools. It makes you feel like you are moving along. I was able to back rivet this skin in 20 minutes and it turned out great. Not bad for starting out with a 1/4″ thick piece of 4″ bar stock I got from a friend and smoothing it out for a back rivet plate. I decided to call it a night. I am sure I said it before, better quit while you are ahead than risk really messing something up.