Empennage is COMPLETE!!!

I was eager to get home tonight and finish the last couple of items on the elevators. After all, these are the only items left on the entire Empennage as far as construction goes.

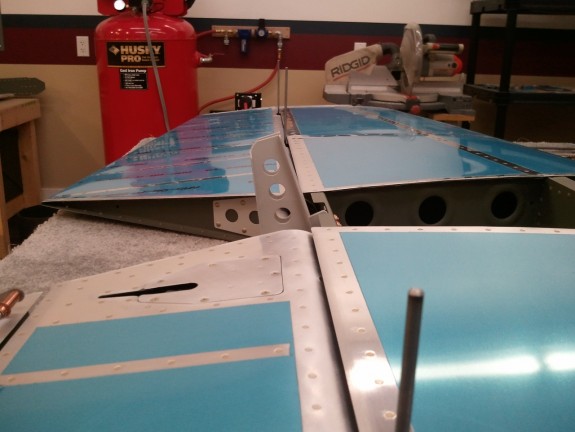

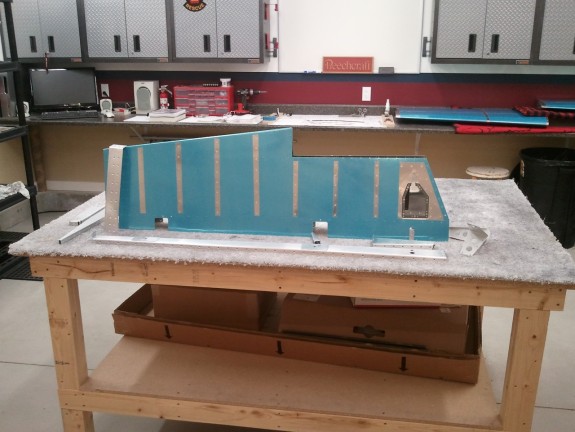

I cut and filed the last two HS skin clearances for the counterbalance arms on the top of the skins. The elevators can now swing free top to bottom. It was cool to just stand there and see them move through the travel range. They look like airplane parts for sure. At this point, drilling the horns for the center pivot bolt is the only step that remains.

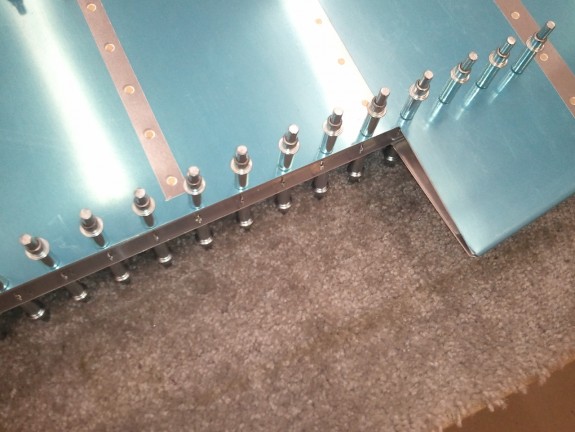

Last weekend, I placed my order with McMaster-Carr for the requisite 8491A784 drill bushing to assist in tackling the drilling of the horns for the pivot bearing bolt holes. It arrived this last Wednesday. It was not cheap. It appears to come slightly oversize for the 1/4″ bolt hole in the bearing. Actually, I think the bearing is slightly undersized. To fit the bushing inside the bearing, I had to put the busing in my drill press and simply sand it down little by little until it slides into the bearing.

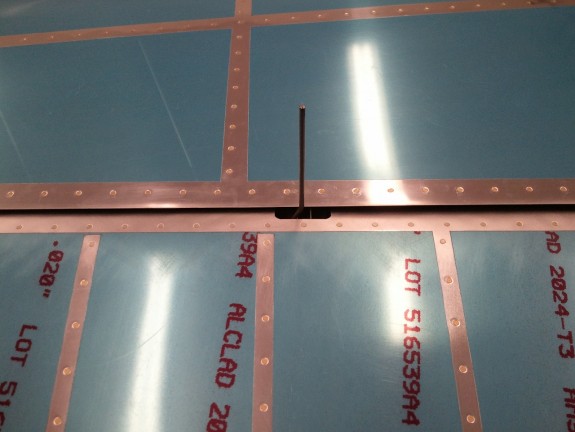

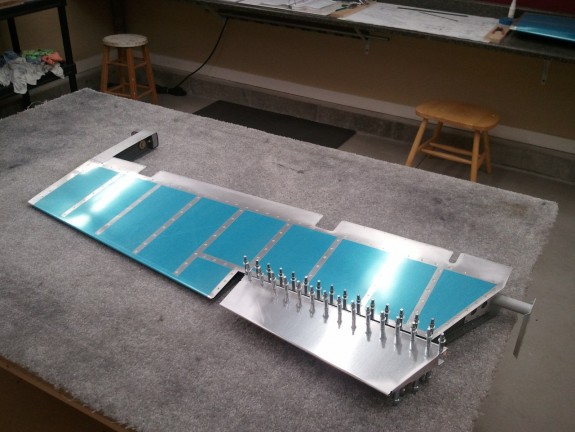

Above you can see the bushing in place in the bearing and my #40 drill bit inserted. This centered the drill bit and kept the bit from wandering. I clamped the right elevator in trail of the HS and committed to the hole. The bit drilled through pretty quick. I then opened the hole up with a #12 bit and then finished with my step bit to a finished size of 1/4″. I repeated the process on the left elevator.

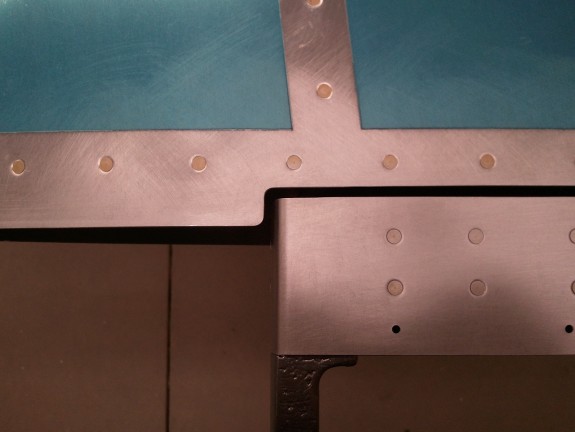

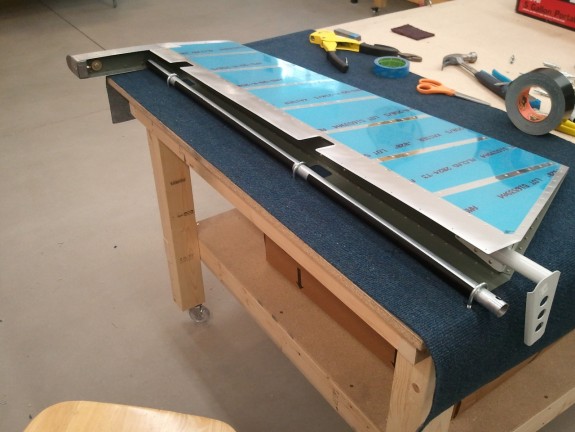

Above is the finished result on the left elevator horn. All in all a pretty clean hole. I then installed the elevators back on the HS and to my delight, the two horns and the bearing all lined up and I was able to get the bolt in and some spacer washers in place per the plans. I then replaced all the temporary hinge pins with the bolts that go in each hinge point and tested the travel again. No binding from top to bottom travel. I was also enamored with the smoothness of the travel. Silky.

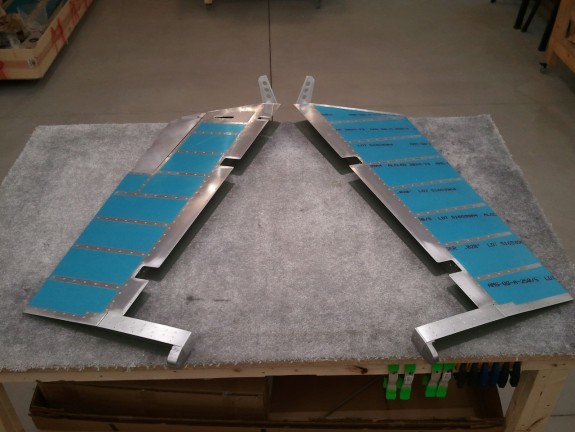

As far as major construction goes, the Empennage is COMPLETE! Only items that remain are the fiberglass tips on the Empennage parts. These will wait until later as they can tear up tools because of the composite nature. Van’s suggests that you wait, though not required, until you are doing more fiberglass work later on. Now I need to find a way to safely store these assemblies in the shop to get them out of the way and save them from damage. Time to move on to the WINGS!!!!