Elevator Riblet Fabricated

Giving credit to Jason Beaver again, I liked his riblet design on his work. I emailed him and asked for his process. It was simple enough. Basically, you make a paper template of the riblet until you are satisfied with the fit. Then you copy that to some 0.032″ scrap and cut it out and then bend it with a pair of hand seamers. Sounded easy enough. The thing I liked about Jason’s design is that it tied the trim spar in the elevator to the riblet rather than simply closing off the end like other builders have done. The thought is that it will reduce/eliminate more twisting at the corner of the skin and the spar and hopefully keep cracks from forming in the corner of the elevator skin where stresses are focused. Since the original design was simply to fold over some ears, this may be overkill, but heck…why not?

After some careful measurements, I generated a template pattern on my computer and printed it on a file folder. I have the vector file now if other builders want a head start. I then cut it out and then scored the bend lines and what do you know, it fit nicely. I figured I was on the right track. With some minor tweaking, I updated my file on my computer, reprinted, cut out, bent, and fitted. I had a winner.

I then transferred the pattern to some sheet scrap and cut it out on my band saw. I then cleaned it up on my disk sander and dressed up the edges. Now it was time to bend. I placed the sheet stock in the jaws of my hand seamer and started to it. That is where all heck fell apart.

One of the challenges of bending metal is knowing where to bend to get the part to be the right size post bend. Paper and metal are totally different beasts. The other issue was the little flanges to capture the spar. Bending these takes a little finesse over the large flanges. As I was bending the first little flange, it cracked right at the bend line. There goes that attempt. I actually cut off the smaller flanges and web and figured it could work as a riblet just fine. Turns out, it fit quite nicely.

I still wanted to make one that captured the spar. So I repeated the process on try #2. I slowed down some and took my time on the smaller flanges this time. It paid off, however, the web of this riblet was too wide and the rib did not fit very well.

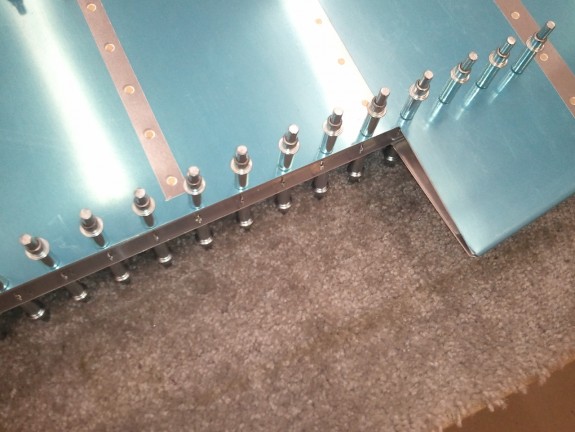

They say that the third time is a charm. It turned out to be true here. I was able to get another cut, bent just right with no cracking, and fitting nicely. Mine is not as tight to the trim spar as Jason Beaver’s rib, but it fits and works and it really stiffens up this area. I match drilled the smaller flanges to the spar/skin. Next up is match drilling it to the trailing edge.

It was time to call it a night. Here you can see the rib in and ready to be drilled to the skin. All in all, it turned out OK. Bending may have been easier to try, but at this point, I like the clean look the riblet creates and the added rigidity it also adds. Time will tell if the extra work to get it to tie into the trim spar was worth it. Thanks for the idea and tips Jason B!