Every Little Bit Counts

After work, and my requisite hug and kiss I give the wife to say hello, I ran out to the shop to tackle another small task on the Horizontal Stabilizer. I was able to get the left HS skin notch for the counterbalance cut out and filed. I then got the call for dinner and had to put the tools down. I love having a dedicated space to build. Only one more step on the underside of the HS to go.

Once dinner and Family Night stuff was over, I headed out to take care of that last task. The lower flange of the HS rear spar interferes with the full deflection of the elevator horns. To solve this problem, you need to notch the flange to clear the horns. I am sure that it would have been possible to do this step earlier during the construction of the HS, but the manual has you wait until the elevators are mounted to do it. While the elevators were mounted on the HS, I made a mark on the spar flange in line with the outboard edge of the horns. I then added 1/8″ to that to give the horns clearance along the sides.

I had to remove the center bearing assembly that I had previously final torqued the bolts, but that was no big deal. I then masked over the spar reinforcement bars as the plans explicitly say, DO NOT REMOVE ANY MATERIAL FROM THE HS-609PP! I looked at the plans and basically notched the flange flush with the reinforcing HS-609PP bars inside the spar. I figure the lower travel stop that will more than likely stop the elevator horns from ever hitting this flange now so I have good clearance and clean lines.

I also noted as I was completing this step the obvious increase in my expected level of perfection. When I had started the HS, I rounded the corners of the spar where they met in the middle. The corners were not even close in shape though just fine. As I looked at the other parts in progression of completion, I noticed my attention to detail has improved. Perhaps Van, in his wisdom, knew this would naturally occur and left these last tasks where they are to create better results through natural progression. The accuracy of this kit keeps shining through no matter the mistakes I have made.

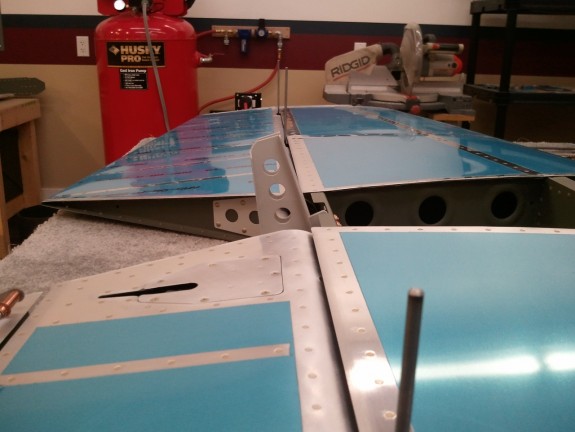

Once the center notch was complete, I remounted both elevators to the HS. To my delight, the horns appear to be very close in orientation to one another. Some other builders, and even the plans, note that these may not be exact as the manufacturing process is not perfect on the horn weldements. Vans has either improved this, or I am lucky, as mine are pretty darn close as you can see in the above picture.

At this point, the spar/skin trimming on the underside of the tail is complete. All that remains is the counterbalance skin clearance portions of the upper side, drilling the center bearing/horn interface, and the fiberglass tips. I may wait to drill the horns when the tail is mounted to the fuselage, but the tips are definitely waiting until the tail is on the rest of the plane per the advice of many builders. Time will ultimately tell.

Stay tuned for the official “Tail Complete” announcement to hopefully come later this week.