The time has come to start the fuel tanks. First up are the infamous “Z” brackets. The manual procedure is pretty universally accepted as worthless. The more acceptable and best result creating method is typically referred to as the “Checkoway” method, named after the Dan Checkoway that documented the process really well, though credits another for the actual idea. Dan has since retired his website, so builders are left to discern from other builder sites the actual process. Several sites that I used to get the general idea were Bruce Swayze’s, Jason Beaver’s, Brad Oliver’s, and a couple others found on VAF when searching “Checkoway.”

[ed. Dan has given full credit to Steve Hurlbut for the idea. Original description can be found here.]

Once I felt I had enough information, I began. I hit all the edges of each of the brackets on the Scotchbrite wheel. Essentially, the “Hurlbut/Checkoway” method is offsetting from center the Z brackets to make it easier to get a wrench on the inboard brackets and to give more room for the pop rivet gun for the outboard ones. It also allows the tank to be perfectly aligned with the wing and the leading edge assembly before drilling the baffle to bracket holes. This eliminates the need for possibly elongating the holes in the brackets to be able to position the tank in the right place. In reality, it is just a better way of doing it.

Inboard Offset Away

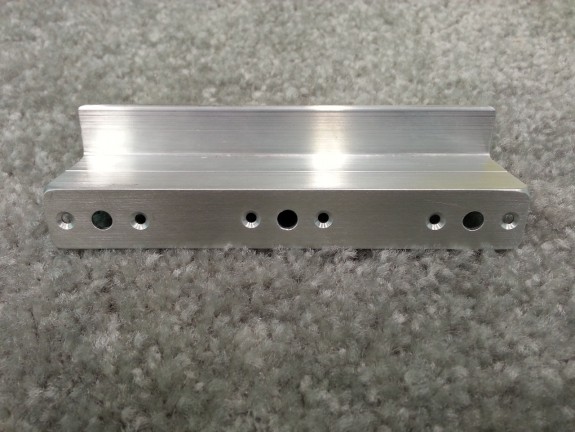

First thing to do is to offset the inboard bracket holes away from the web. I measured several different distances and finally settled on 1/4″ from the outside edge for the inboard brackets. This about 1/16″ out from center (as viewed from the aft of the bracket). This gives just enough room to allow a socket to fit over the head of the bolt that will be used on the inboard of the tank. You then find the exact center of the bracket. Once I did that, I center punched the hole. I then drilled the hole with a #12 bit. I repeated the process for a second bracket.

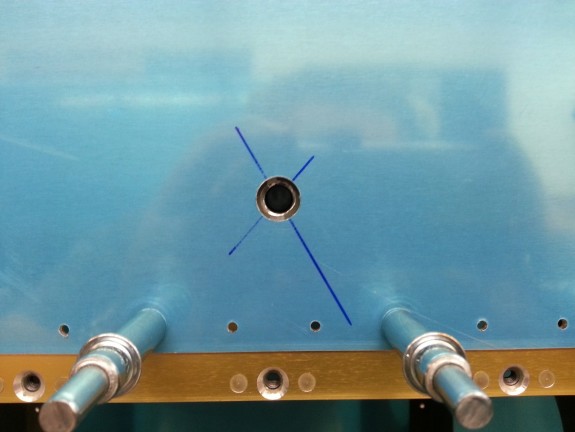

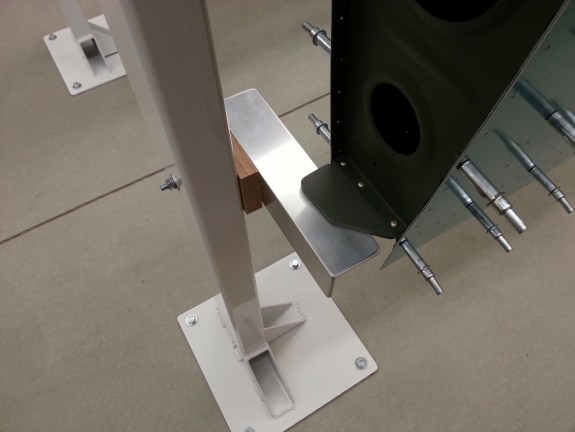

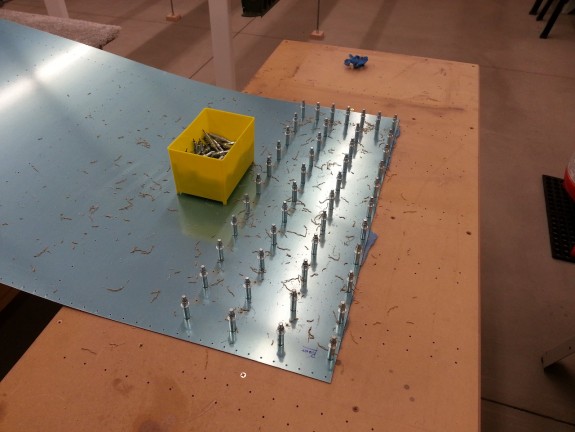

Bolted and Ready for Match Drilling

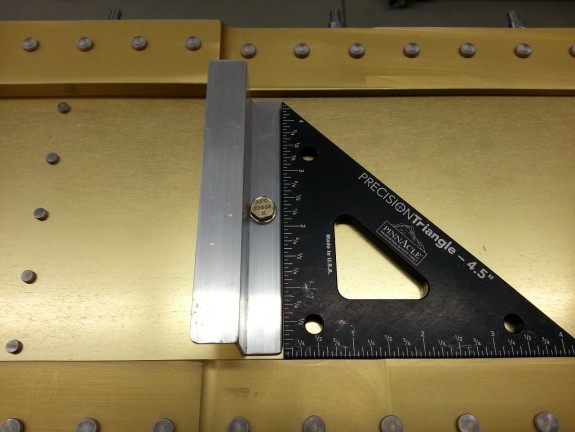

Once the center hole was drilled, I used some scrap AN3-4A bolts and nuts and bolted the bracket to the spar. As you can see above, the bolt is slightly offset from center on the flange. The reason you use bolts is because clecos will allow some movement where bolts will not. You square the bracket to the spar and then match drill the holes remaining using the spar as a guide.

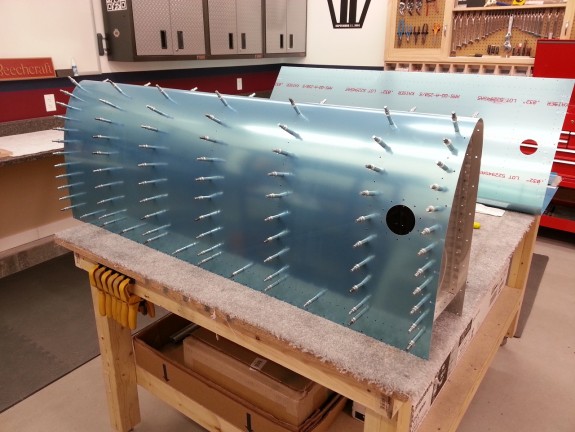

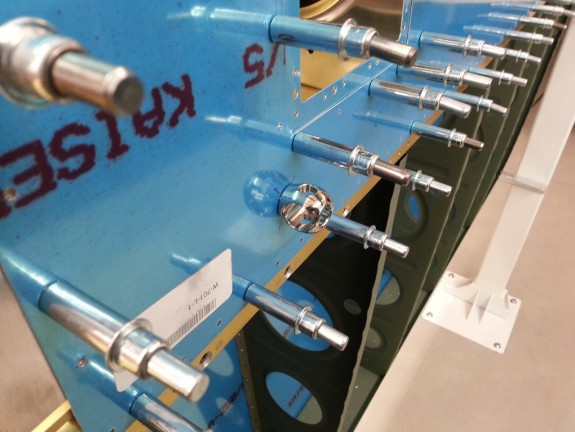

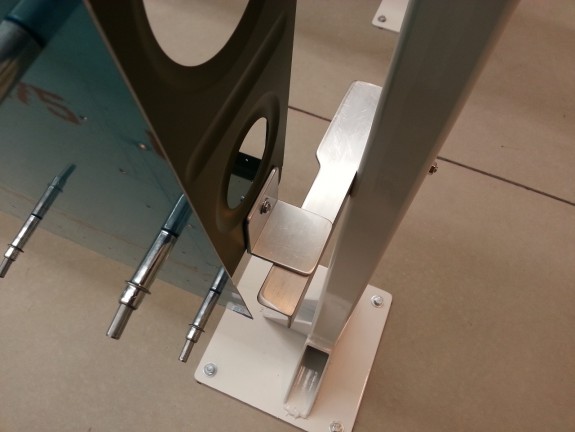

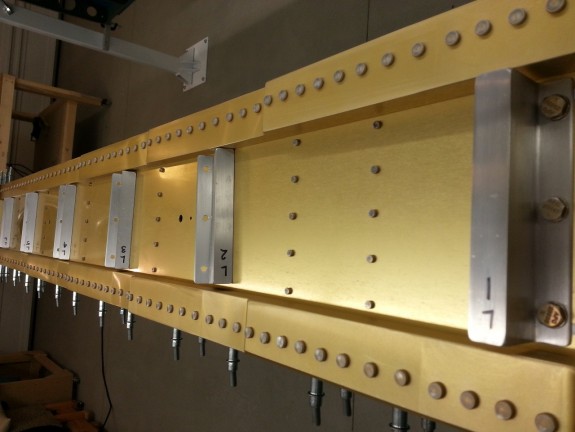

Hey, Math Works!

As you can see from this shot, once the bracket is square, it should be aligned with the holes in the spar along your drill line. I drilled one of the holes through the spar, then inserted another bolt and secured it with a nut, then drilled the remaining hole in each bracket. This insured each was perfectly aligned.

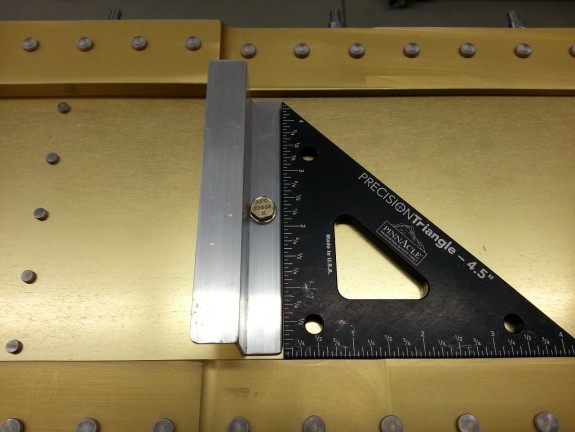

Squaring to Spar

Here is how I squared the brackets. The contrast between the spar, bracket, and the square made it easy to see if they were off. I simply looked to see if the gold was shining through between the square and the bracket. To be double sure, I flipped the square and checked against the other spar bar. Every bracket was spot on.

For the outboard brackets, I changed the offset to 5/16″ from the edge of the flange. Some have gone more, but I figured it was a good compromise. 5/16″ is actually the center of the flange on the aft side but offset in towards the web. This will move the rivets on the other side out from the web. I may still have to get a cheap pop rivet gun to grind down the head to still set these, but not nearly as much as I would have.

I set up my drill press to replicate the center holes on each of the remaining 12 brackets and then bolted them in place on the spar. Then I match drilled them to the spar.

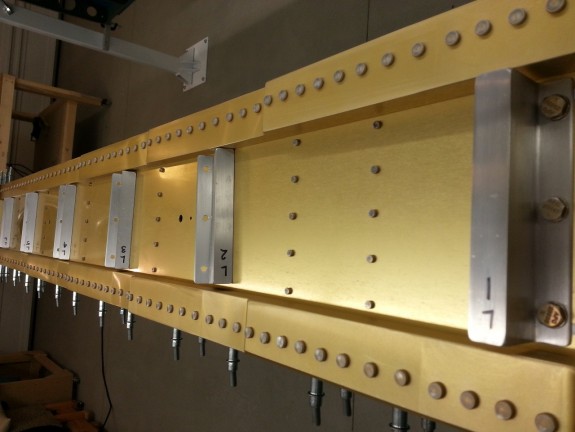

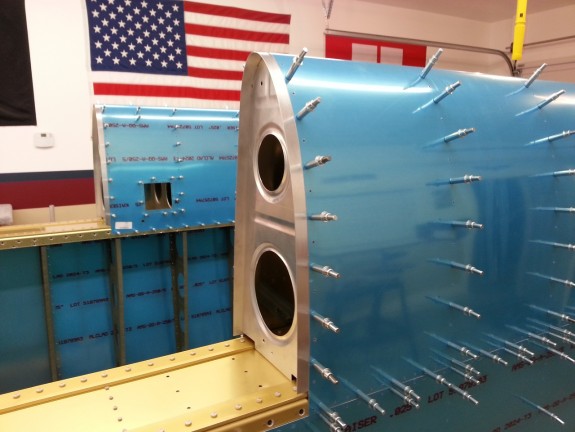

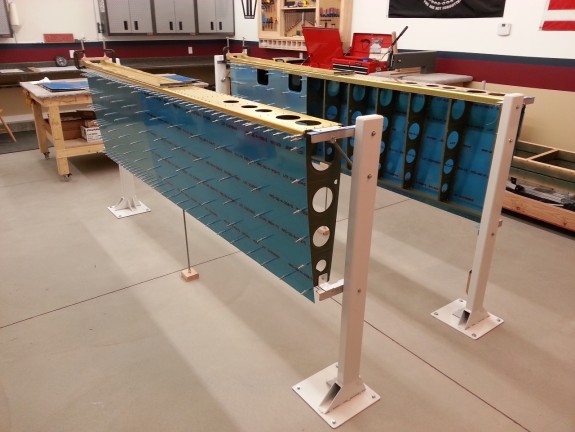

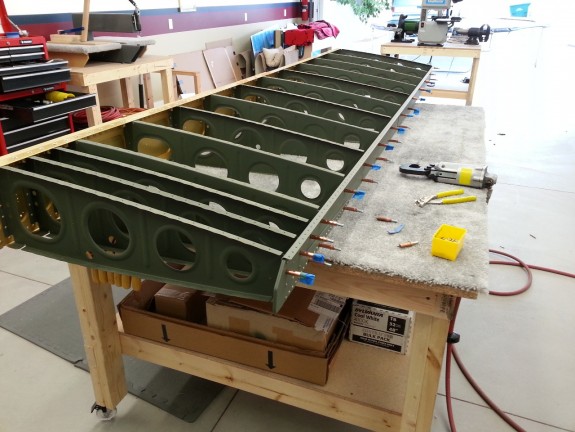

Right Brackets Drilled

Here you see the brackets all drilled and in location for the right wing.

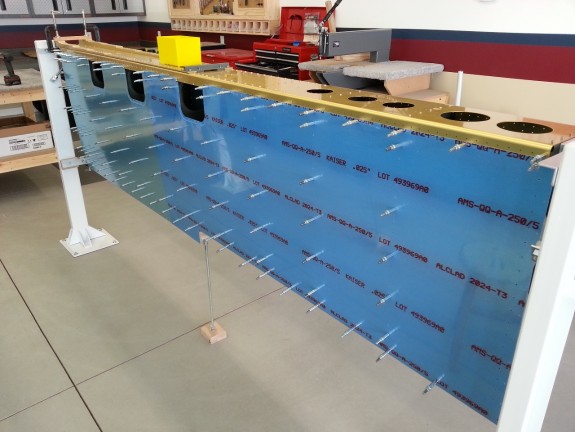

Left Brackets Drilled

Same for the left. These are now ready for the nutplates that will be riveted to each of these brackets. I then installed the three nutplates on each spar for the inboard brackets. It was very late so I called it a night. I hope to borrow a nutplate jig from a friend to make drilling the 72 holes needed a little quicker. Stay tuned for the rest of the procedure next.