Left Spar Nutplate Countersinks Complete

I was able to get some time in the shop tonight and continue the prep work on the Left Spar. I needed to countersink the nutplate locations for the #8 screws that hold the tanks to the spar. Additionally, I needed to countersink for the #6 screws on the bottom that hold the inspection covers on. These countersinks are a challenge only because they are deep enough to open the hole wider than the pilot of the cutter and can allow for it to move around once deep enough. You have to use something beyond the flange to hold the pilot after it cuts the countersink beyond the flange. I have read several build sites that describe what can be done to accomplish this task. Van’s states that you can install the nutplates first and then use the nutplate as guide for the pilot of the countersink. That seemed a little hokey to me, but several builders said that it worked OK. I guess I just did not like the idea of possibly ruining the threads of the nutplate with the pilot of my cutter and the possible chips that could get lodged in between the nutplate and the spar flange.

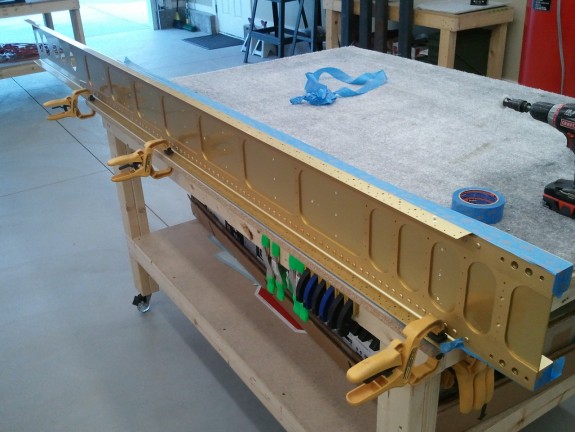

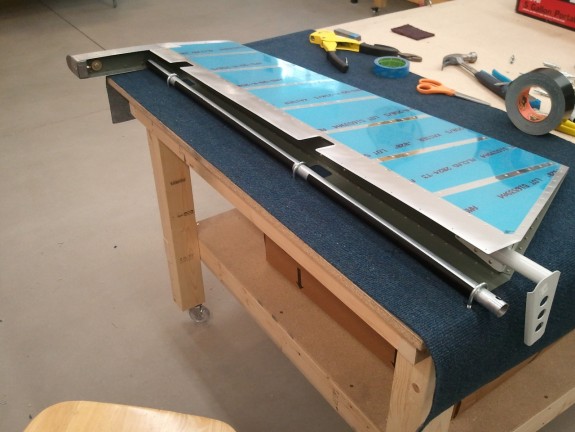

Another option some have used was to use a piece of 1/16″ aluminum angle to back the holes that are to be countersunk. You simply clamp it to the flange and match drill the holes to the angle and then use it to keep the pilot centered in the hole. Since I had my angle from the rudder lying around, I decided to give this technique a shot. In the above picture, you can see that I have clamped the angle to the flange and have already match drilled the center holes with my #21 bit. I then used some clecos to hold it down the flange as I clamped it closer with some alligator clamps.

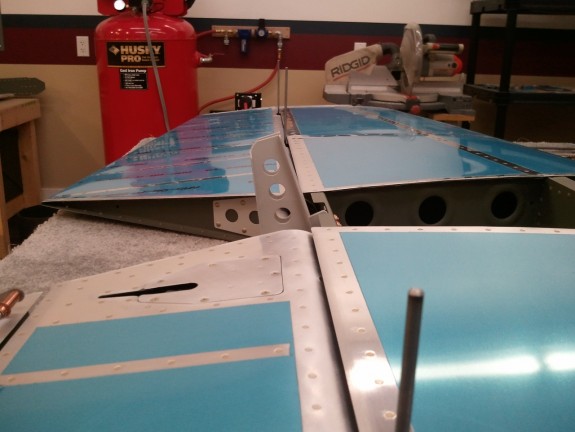

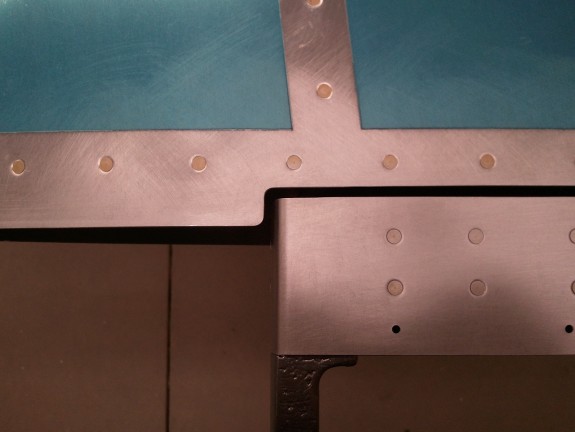

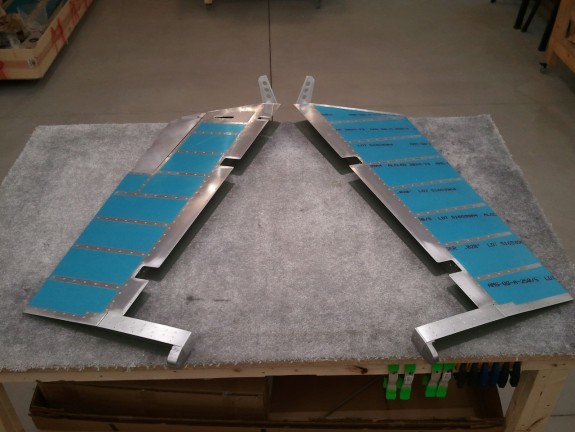

I then worked my way down the flange with my #21 piloted, 3 flute countersink. I tested the depth of the countersink in some scrap. I was aiming for a 0.370″ wide countersink (Van’s states it should be between 0.365″ and 0.375″ in diameter) and was spot on. As I would countersink, I would let the countersink cage nearly bottom out, then remove the chips, then finish the hole. This left a very nice, chatter free countersink. I figure that at .0370″ I can still adjust if needed, but many report that it will work great as is. As each was complete, I leapfrogged the two clamps so I could hold the angle tight to the flange.

Here you can see the angle down the length of the spar flange. The important thing is to not let it wander as the countersink is cutting. This is what eliminates the chatter.

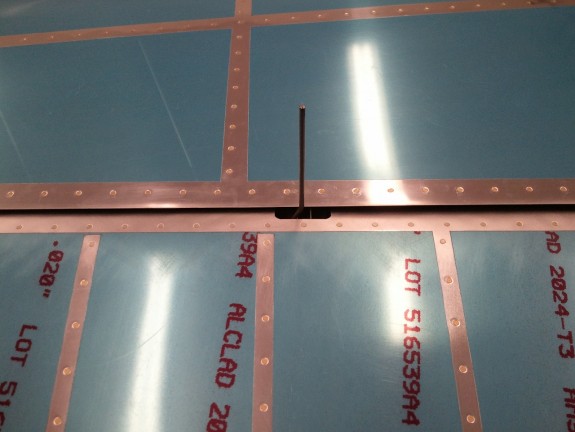

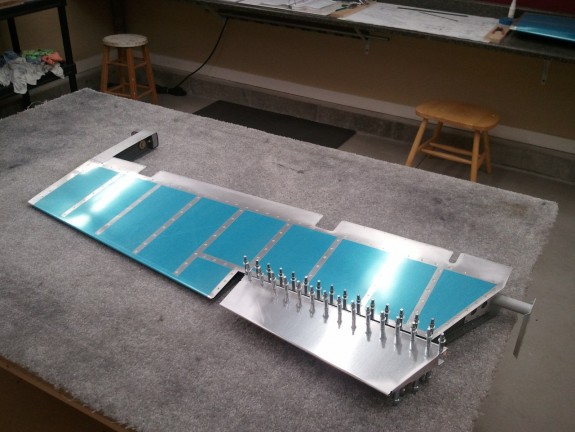

Here you see the #6 holes for the inspection covers to spar interface. I used the same piece of angle to back these up. I simply offset the angle until I had no overlapping holes from the #8’s and match drilled them with #30 bit. I then used my #30 countersink cutter in a different cage set up to cut a countersink with a 0.312″ diameter. I found that Van’s recommends a countersink no greater than 0.3125″ for #6 screws. I tested on a scrap piece and then hit these. They come VERY close to the edge of the flange, but according to other builders, that is expected. Once complete, I was left with many shiny and chatter free countersinks that are ready for nutplates. The angle backer trick appears to have worked nicely. Now I simply have to repeat the process on the right spar. Thankfully, the angle I match drilled should line up with the holes already in it from this spar. I simply need to clamp and cut.

It was bed time for the kids and I just finished the countersinks and was cleaning up the shop when I got some visitors. My second son Alex is a real curious one, so we chatted a little as to what the gold thing was on the bench. I asked my wife to take a shot of me working/posing with the parts and he weaseled in the shot. Hopefully his curiosity sticks because I will need a bucking partner on the wing skins soon enough. With everything learned on the first spar, the hope is that the second will go a little faster.