Weekend Adventures in a Baby Beech…Virtual Log!

This last weekend was my birthday. It was also my wife’s 15 year High School Reunion in Southern Utah (near KDXZ). Most can imagine where a guy would rather be on his birthday. (Some examples include; Dentist for a root canal, Proctologist, beauty salon getting leg hair waxed off….you get the idea) She really wanted to go (dang cheerleaders) so I proposed a compromise. “Let’s Fly!” She agreed.

The weather was forecasted to be severe clear with a large chance of sun. Temperatures were to top off at 85 degrees in SLC so that put the DA at about 6500+ MSL. Not bad, but something to consider when potentially loading a plane to gross and heading off for a cross country flight. I spent the next couple of days planning the trip, doing performance calculations, getting W&B worked out, and watching the extended forecasts.

Turns out, it was going to be a perfect weekend to fly. We have made the trip to Southern Utah once before as a whole family, but everyone was a little smaller then. My kids are growing up too fast. Needless to say, the math all worked out and as long as we did not pack the kitchen sink, we’d be OK.

Seeing that it was my birthday after all, my generous mother-in-law offered to watch the kids for the night once we arrived so my lovely bride and I could get away to a B&B or something. That again got my wheels a spinning in my head. We looked at options locally down south but all were pricey and not easy to get in short notice. Then it hit me….”Let’s go to Vegas, Baby!” Again, she agreed!

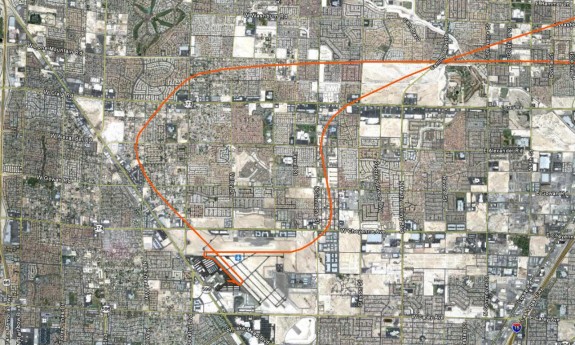

I had heard that North Las Vegas can present a challenge getting in an out. I like a good challenge, and I really like showing my wife how fun interacting with ATC can be. So KVGT it was.

The day of the trip arrived. I decided to take the day off work. As such, I was asked to fly a CAP mission flight that morning. The kids were not out of school until at least 1400L so heck, why not. By noon I had logged another 3.9 hours in a CAP G1000 Turbo 182. Spoiled I know, but I rarely argue when the US tax payers are paying for my flight time. On my way back home, I stopped off at my home base and pre-flighted the Sundowner, got all my charts in order, plugged in all the headsets, and generally got the bird ready to show and go.

Got home, loaded the kids and wife into the van, and headed off back to the airport. Shoe horned all them into the Sundowner and started the engine. At this point, we were at the height of the day as far as temps and density altitude. I quickly checked my takeoff and climb numbers to insure we were good to go. With the math giving a green light, we taxied on to Runway 34 and throttled up.

For those of us that operate at higher altitude airports, we are used to reduced performance from the get go. I chuckle at times when other owners of my type of aircraft will get on the forums and comment how they had to get to 4500 feet to get cool temps and smoother air. U42 is at 4620 MSL! 🙂 Climbs of 250 fpm at gross are a godsend here. I love it when I can get over 500 fpm solo. You guys down near sea level have it good.

The takeoff was as expected, slow and the climb was shallow. We got to pattern altitude about mid field on the downwind. The stall horn chirped a little on the upwind climb. Needless to say, I was watching the airspeed like a hawk. I have been using the mousevator flap technique for some time and it made a ton of difference with this departure. Once established on the departure to the south, the Sundowner climbed OK to our cruise altitude of 8500 MSL after we dodged the SLC Class B and a few Restricted Airspace areas over Camp Williams (you don’t want to be shot at by a tank do you?).

Interestingly enough, I had an Piper Archer from a local college flight school just ahead and below us. Either he was throttled back a little, or I was going faster with a tail wind at my altitude, but we kept pace with each for half of my flight until he landed. I was pleased with my little bird as we chatted back and forth a bit on the radio. The other pilot was clearly a CFI in the right seat.

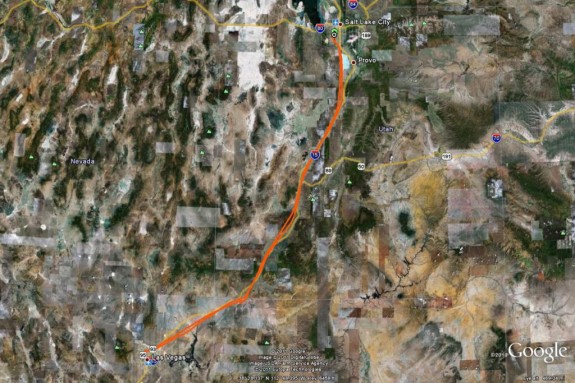

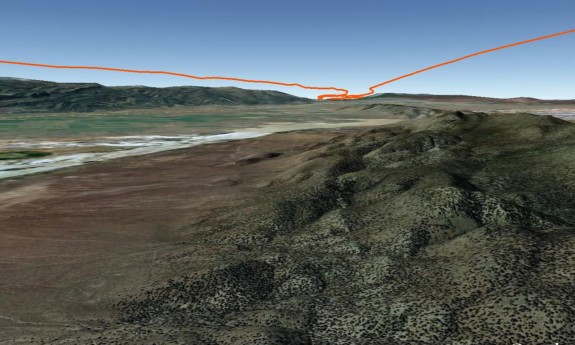

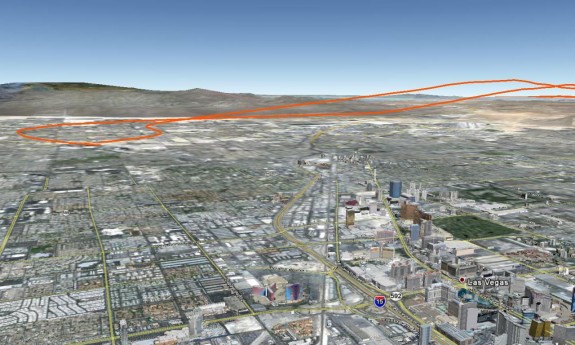

One of the items I love to fly with is my Garmin 496. The refresh rate and the information it provides are simply excellent. I love to download my tracks when I make long flights like this to see how the plane behaved and the route I took and the telemetry it shows. Here you can see an overlay of the route at altitude. The left track is my track down south and the right is the return leg back home. Notice anything? The route down was pretty bumpy. While it is typical this time of year to get turbulence, this particular afternoon posed a bit of work for me. I love how the recording resolution of the 496 actually captures the subtle changes in altitude and directions. I was constantly having to adjust the altitude and power with all the thermal activity. At some points I was getting 1000 fpm swings.

I apologized to my wife for all the bumps. The kids were clueless as they had long passed out. She told me she prefers the turbulence at times as it makes the ride fun. If she knew how much more work it was, she may change her mind. I love that she loves to fly with me. I cannot wait when the RV is done and we can travel faster and higher and farther together. The pattern of bumps continued the entire 2 hours of this leg.

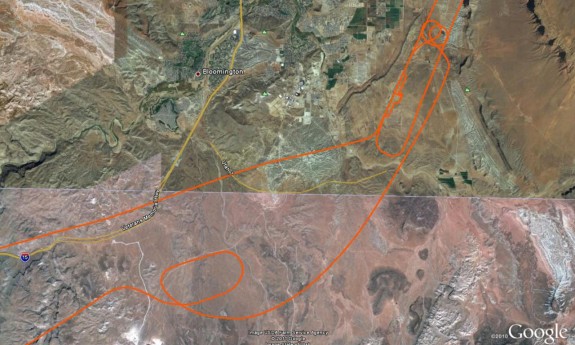

We kept chugging along to KDXZ. As you can see from the shot above, KDXZ is too new for even Google Earth. It was finished late last year and replaced the long time operating KSGU airport. This was the first time I had made it down both personally and with CAP, so I was anxious to try out this new facility. The approach was pretty straight forward. I began a decent at KCDC and called straight in runway 19. At this point I was 20 gallons lighter and I had a perfect touchdown. The surface of KDXZ is VERY smooth. I had to check to see if we had landed because the roll out was sooo nice. The fact I was no longer getting bumped around actually should have clued me in we were down. 🙂

We had arrived. The FBO came out to greet us and asked if we needed anything. I asked for fuel to the slots again and if he had internet capability. The FBO is sooo new, the building really was a shell still in process. The bathroom at least had a working sink and toilet. The tile for the pilot/crew shower was still being installed. Looks like it will be a great facility when complete.

My In-Laws arrived at 1800L and we discussed options again. At this point, I had not booked our room in Vegas just in case our plans may change or something came up. It was then decided that my wife and I would ditch the kids and continue on to KVGT. I asked the FBO if I could use his computer and then checked Hotwire for a room in Vegas. They came back with a couple of cheap 4 star rooms downtown so I snagged one. If you don’t know how Hotwire runs their really good deals, you do not know the hotel until after you book and pay. So to this point I was rolling the dice. Turns out, our room was at the Golden Nugget and we were confirmed…so time to get going.

We said goodbye to the kids, thanked the in-laws for taking them, and piled back in to the Sundowner for 1 more hour of fun.

A friend of mine once worked for Vision Airlines (based at KVGT) helped me get a plan of action together to deal with the LAS Class Bravo and get into KVGT. He said to get a TAC for LAS and once off KDXZ, contact LA Center for Flight Following. They would then hand me off and then follow directions to the letter and I should be OK.

Plan in hand, TAC in hand, wife strapped in, we took runway 19 at KDXZ for departure at about 1830L. With 1 hour in flight, we should be at the hotel near 1900L with the time change. Once off KDXZ, I called LA Center. The controller was really nice and I declared my intentions. He gave me a squawk and off we headed VFR and own navigation to KVGT.

As we got over Mesquite NV, I briefed my wife on the fact that LAS Class Bravo will be busier than anything she and I had experienced in SLC Class Bravo and the need for a sterile cockpit when LA Center hands us off to LAS Approach. She understood and we prepped for the decent from 8500 in. Up to this point, LA Center was pretty quiet. It turned out to be a foreshadow of things to come.

As I was 45 miles out of KLAS, LA Center handed me off to Nellis Approach and wished us a good night. I thanked him for the help and switched to Nellis. Upon initial contact, Nellis Approach gave me the following; “Sundowner 76R, cleared into Class Bravo, direct North Las Vegas, own nav, maintain VFR, decent at pilot discretion.” I was 45 nm out and he gave me a path right to KVGT. I could not believe my ears. I figured it would change as I got closer. After all, it was still only 1815L now that I had made the time change. I was almost a little bummed as I wanted a challenge.

We continued inbound and began a nice shallow decent. I stayed under Class Bravo until I reached the segment that went to the ground. I was cleared so I went. I told my wife…”ok, now it should get busy.” I kept on inbound until I was abeam Nellis on the South end when Nellis called and said; “Sundowner 76R, contact North Las Vegas Tower, goodnight.” Between my initial clearance and instructions to now, there were NO other calls to me or anyone else. I could not believe it. Am I really going to get into KVGT this easy?

I read back my instructions and switched over to KVGT Tower. A nice happy sounding controller acknowledged and gave me one traffic advisory for a student doing T&G’s and then said, “Sundowner 76R, make left base, cleared to land runway 12R.” Did I really get cleared to land? Is that really it? Did Vegas shut down? Is there something wrong? After a couple more traffic advisories, I was on final with 12R in sight. Had a great flare, touch down, and roll-out! Where are my check pilots when I need them. 🙂

Tower advise to contact ground off runway and have a nice night. I looked at my wife and said…I have had more trouble getting on the ground at U42, and uncontrolled airport, than this was. She was surprised too. We taxied up and followed the “follow me” van and parked. Nice ramp worker got out, grabbed our bags, helped me tie down and put our cover on, and hauled us off to the terminal. He called dispatch to get us a cab.

After check in at the desk was complete, we headed out front and there was our cab. We headed into town, got checked in, got our room, liked it, then headed out for dinner. Vegas is not exactly our kind of town. In fact, the primary reason for us going there was the challenge (or perceived) of getting into the area via a general aviation plane, and to just be together and have a break from the kids. Being in Vegas was not a high priority. She and I feel that if you are somewhere you cannot take your kids, then you should not be there. Vegas is not for the kids. None the less, the food is good and the room was nice, so we focused on those aspects. We had a good Italian dinner at the Grotto in the Nugget and then walked around a bit. That was enough for both of us. After all, I had already logged 7.2 for the day in 2 separate planes at 4 different airports and travel to/over 4 separate states. That was a great birthday present.

We called it a night and headed back to the room. Golden Nugget as really done a nice job renovating the hotel. Nice place…especially for the rate we got it for.

After a restful night ;-), my wife and I packed up and headed down for breakfast. We found a nice restaurant and sat there smiling as we watch the morning in Vegas start. Needless to say…it is REALLY quiet in the AM. It was actually nice.

Caught a cab and headed back to KVGT. I thought again, maybe now we can get some ATC busy action. No such luck.

Once pre-flighted and running ground gave me a heading and a frequency to call when established. Run up complete, call made to tower, and we were cleared for departure runway 7. I turned to 340 when off and contacted Nellis Approach. His response was; “Cleared into Class Bravo, direct KDXZ, own nav, altitude at pilots discretion, maintain VFR.” That was it until I was cut loose outside of Bravo.

I could not believe it. Being that it was morning and temps were cooler and it was just the 2 of us, the Sundowner climbed like a champ. Being at 2200 MSL did not hurt either. We were at 9500 MSL by the outer limit of the Class Bravo and heading NE.

The air was smooth as glass and the visibility was unlimited. Sun was just above the mountains and we had a great view of Lake Mead. Stupid me forgot to get out the camera. Did not matter, I was flying my plane with the love of my life next to me holding my hand. We had a little head wind slowing us down, but I had all morning to burn as the reunion was not until later that day. I love to fly, but I really love to fly with my wife.

I declined flight following on this leg. I wanted to just enjoy the view and enjoy chatting with my wife. The leg is relatively short and the traffic apparently was light. Was a good choice.

As we began our decent into the KDXZ area, a King Air called in and stated that he was on the RNAV approach for Runway 1. He called out his DME and we were at the time, about matched in distance and on converging courses. I opted to let him continue in on the approach and I simply executed a 360 degree turn to give him room. He was spinning 2 engines and I only had one and lots of time. I then resumed the inbound course as he executed a circle to land for a T&G on runway 19. I watched as he did his landing and climb-out and off he went. He thanked me for my help and was gone.

Now it was my turn. I called established on downwind and noticed that a local freight carrier had taxied to and was holding short of runway 19. I pressed on thinking he was waiting for me to land and would then go. WRONG!!!!

As I called my base turn, he began to roll out on the runway….I thought…”seriously, is he going now? I just called Base genius!” I then decided, I do not want to be anywhere near this guy when he departs…so I will do a base 360 degree turn to the outside. Not exactly standard, but I did not want to do a go around and have him climb right into me even if I side stepped the runway. I advised that I was doing my 360 and got no reply from him. After coming around to complete my base, I looked over and HE WAS STILL ON THE THRESHOLD!!! So I called another 360 at which point he simply said “OK” and then throttled up and went along his merry way.

After the second turn around, I saw him climbing out and I said to myself, “Let’s get down and off the runway before he realizes he left his brain on the ground and comes back for it!” I came in and made another sweet soft landing and taxied off. Shortly after I pulled in, a nice guy in a REALLY nice Comanche 250 landed and taxied in. Turns out he was one of the original creators of SkyWest Airlines. Nice guy. He and I got to talking about the tool that just took off as he heard all the traffic and he said, you did the right thing…stayed alert and out of the way since he and I were the only ones that were clearly paying attention.

The FBO guy came out and also said he did not know what the dudes issue was, but he felt that he was not all there either. Apparently he seemed off in the next dimension when he was prepping to leave. Both the FBO and I agreed that we would submit complaints to the Company advising that there was a near incursion by a clearly dysfunctional pilot within their ranks.

The rest of the day was pretty routine. In-laws picked us up, we reunited with our kids, went to the reunion, and ended up at the in-laws house. I advised them all we needed to get to bed early because I wanted to be wheels up no later than 0730 the next morning. They complied and we all went to sleep.

The next morning we arose to a perfectly clear, star filled sky with the hint of sunrise to the east. I saw a couple of shooting stars as we loaded all the family up. Then we drove for 20 minutes back to the new airport. For those familiar with KSGU, it was centrally located right in the middle of town on a mesa. It was a unique airport as the terrain fell off on both ends of the runway. If you missed it, it was a bad miss. It is a shame it had to go, but progress is progress.

The new airport is out in the middle of nowhere and the road to get to it is very long. You nearly have to go to Arizona and then back north to get there. Not as convenient, but the facility is very nice and will support future expansion. As a side note, one of our CAP Cessna 182’s was the first Piston Single to ever land on the new strip. Governors order.

We arrived, pre-flighted, checked the WX, packed in, and got going. The early AM departure was sooo much better for the climb and the smoothness. The FBO let my in-laws drive his golf cart to the edge of the taxi way to send us off. Nice guy.

As you can see in the second picture, the return trip was super smooth. Once I got to cruise and leaned out the engine and trimmed it, I think I touched the yoke maybe 4 times until decent. The rest was a simple rudder peddle press or two. All the kids and the wife were asleep and the traffic was super light. It was heaven on earth. I had the mountains to the right, the desert to the left and home ahead. This is peace.

Decent in was uneventful. Had to dodge a few local guys doing pattern work and then snuck in. Another sweet landing at the end of the trip capped it off. We taxied back and unloaded and waited for the fuel truck to arrive.

Once I unloaded and got everything ready to push back, I noticed a couple of guys looking at a hangar mate’s plane. It is an old Cessna 152 he uses for flight training. Apparently in runup before a flight, his wing met another planes propeller. Neither won the battle, but I think this poor old bird is done. The prop went right through the spar so a new wing will need to be located. I do not know the extent of the damage to the other planes prop/engine, but I imagine it will not be cheap. I wish them luck. It is a gnarly reminder to always be vigilant in all phases of aircraft operation.

We were fueled, pushed back, tied down, loaded into the minivan and headed for home. We had just enough time to get to church! Good thing, cause I had many things to be grateful for over the weekend and needed to focus on Him for a bit. After all, I did just have a great birthday weekend and logged 11.2 more hours!