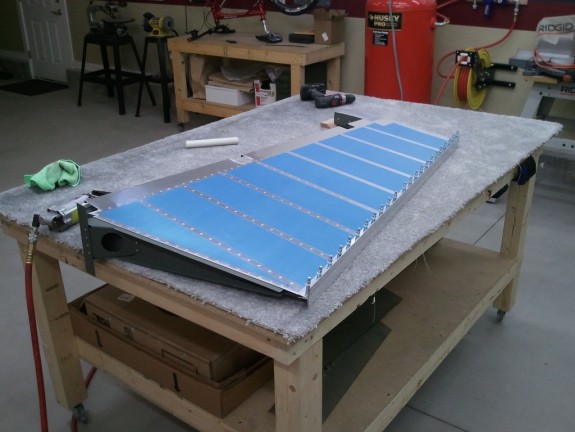

Riveting as the Space Gets Sparse

Today at work, the USPS Santa delivered a couple of new tools. I have been meaning to buy a no hole yoke for my squeezer and since the last rivets on the top and bottom ribs are really hard to get to the shop head…it was time to take the plunge. So I hurried home, took care of some “honey-do” items and then set up the new yoke on the squeezer and attempted to get the last of the rivets that I was not able to do during the last build session.

Turns out, I was able to get all the rivets on the lower rib with no issues. The yoke shines. I then got four of the six remaining on the upper rib. The last two are simply too tight. I tried the indirect riveting method as shown here:

Here is a shot of the “No Hole” yoke in my squeezer. I wish I had bought it earlier because looking back, I could have used it in some other spots on the other parts of the tail I have completed so far. If you are just getting started on your tools or thinking what you need…put this on your list along with the longeron yoke.