Wing Walks Drilled

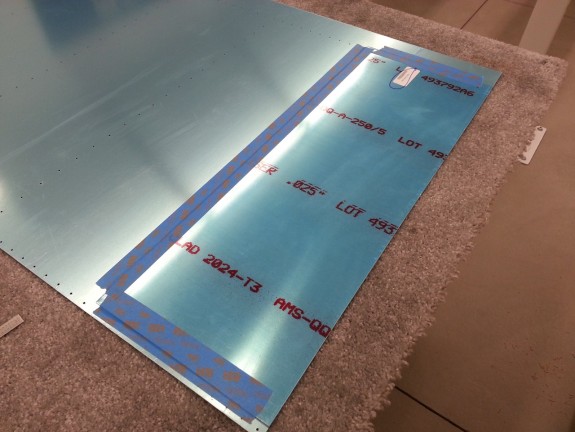

I decided to get the wing walk doubler sheets knocked out. For some reason, Van’s ships two 10″ x 48″ x 0.025″ sheets to make these wing walk doublers from. It seems strange that they want you to cut these down to 9 3/8″ x 26″ and then match drill them. Perhaps this contributes to the 51% required to be completed by the builder, or maybe, they just did not feel the need to punch these. Either way, it has to be done. I have read that some builders simply cut the sheets to the 26″ lengths and leave them 10″ wide. I thought about this, but I figured that I would stick to the plan dimensions.

The next question was how to trim these. I called a couple of friends that work with people that do sheet metal work to see if they had a metal shear. After a little more thought, I figured I could just use my shears and cut them close. That is what I ended up doing. I simply measured out the cut marks, sheared them close, and then filed to the line. It took me about three minutes for each of the doublers. I probably saved three or four ounces trimming off the 5/8″ down the side, but every ounce counts…right?

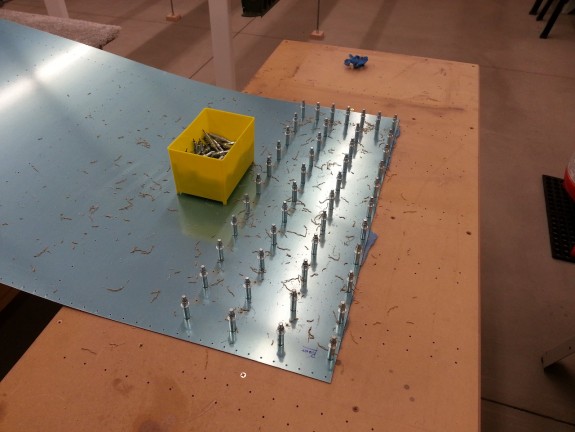

Once the sheets were cut to size, I lined them up per the plans. I then taped them to the underside of the wing skins. It was time to flip and drill. I pulled over my bench that I used to match drill the rudder stiffeners and began to do the same for these holes.

Here you see the end result of the match drilling. It went pretty quick and painless. They are now ready for mounting. Despite being late, I decided to get the doubler and top skins clecoed on to the spars/ribs. Once the skins were on, I cleaned up the shop and called it a night.