Wings Begun, Spar Countersinking on the Left Spar

I had originally planned to take the day off from work to participate in a State/CAP exercise. The State of Utah decided that our assistance was not needed and they were going to spin down. So I had the day off…and I debated if I should go in to work or use it for fun. Fun it is. I spent most of the day building an empennage cart to store my finished tail parts in and get them out of the way. I will outline that in a separate update.

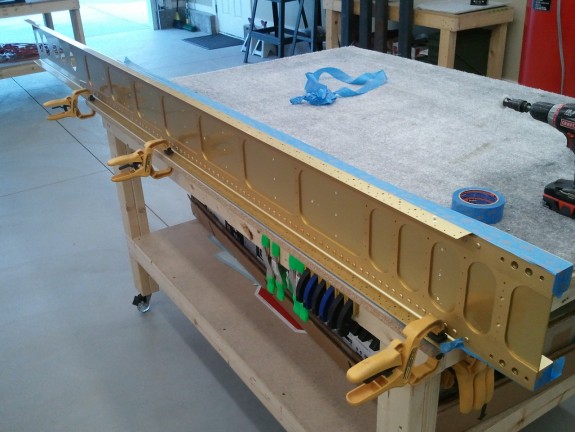

Once the cart was complete, I organized the wing kit crate parts and emptied the the crate. I also emptied the spar crate and pulled the spars out of the shipping plastic. After a close inspection, and only finding some minor nicks, I decided to start with step one of the wings…countersinking all the nutplate attach holes for the tank/inspection cover screws. So I chucked up my #40 piloted countersink in its preset cage, ran a test hole in some scrap, and started on the #40 holes on the spar flange of the left spar.

You can see here that I used some masking tape on the spar. This was to protect the GOLD anodization as well as keep chips from the countersinks from falling into the valley created by the spar channel and the spar bars. It works great. The spar is a work of art. It still amazes me that this chunk of metal can withstand +6 G’s. Engineers are cool. Once all the #40 holes were done on the top, I flipped the spar over and did the bottoms. I used my cordless drill on the low speed setting. More torque, no chatter. I tested all the holes by dropping a rivet in. Every one of them is perfect.

I was able to get all the #40 holes done on the left spar and then the battery died on the drill. It was late anyway so I called it quits. I think I will use another trick I saw on the larger holes. Basically, I will match drill the larger holes with and #21 bit to a cheap piece of aluminum angle picked up from the local Lowes aviation supply. Then I will countersink the holes with my #21 piloted countersink to the correct depth for a #8 screw. The aluminum angle will provide more meat for the countersink pilot as these holes will end up with a knife edge on the bottom. This should eliminate chatter in these holes because the pilot will not wander as the hole in the spar flange opens up. Van’s has you install the nutplates and then use them for centering the pilot…hmmm.

We’ll see how it works out in the next couple of days.