Left Elevator Work Resumes

I decided now that I have heat, I needed to get back to work on the plane. It has been a few months and life has been busy. Since the last build session concluded with the match drilling being mostly complete, and I keep a good list of where I am in the manual, starting up again was a breeze. I got back to work prepping the rear trim spar (E-606PP) for the trim tab. I needed to disassemble the spar from the skin and countersink the upper holes where the hinge for the trim tab will go.

I set up my countersink cage with my piloted countersink to get these done. Here is where I made a small error. Since the spar is .032″ thick material, and the holes have to be a little deeper to accept the dimple of the skin, I forgot that it may open the hole a little more which will allow the pilot to no longer center and cause chattering. That is what happened on the first hole. Once the hole was opened up larger than the pilot, it made a real mess of the hole. The pilot was able to wander all over.

Some may say that the larger hole is a real problem. Traditionally yes it would if the spar being countersunk and the skin were the only parts being riveted together here. However, eventually the trim tab hinge will be added underneath, and this spar will be sandwiched between the hinge and the skin. There will be plenty of support for the shop head and the parts will lock together just fine.

So how do you keep the pilot from wandering? I grabbed a piece of scrap sheet stock and simply matched drilled it to the spar and clecoed it to the spar so that as I cut the material out of the spar hole, it still had a good hole for the pilot to continue to hold the cutter solid. This worked great for the rest of the holes that had to be countersunk.

Once the holes on the top were done, I dimpled the rest. As for the first chattered hole, I decided I would finish the rest of the hole prep and then decide what to do with this one. As I was dimpling the underside of the spar, I missed a hole with my dimple set in my pneumatic squeezer and punched a hole bigger. At this point, I decided it was time for a new rear spar. As cheap as the parts are for the tail, it was an easy decision.

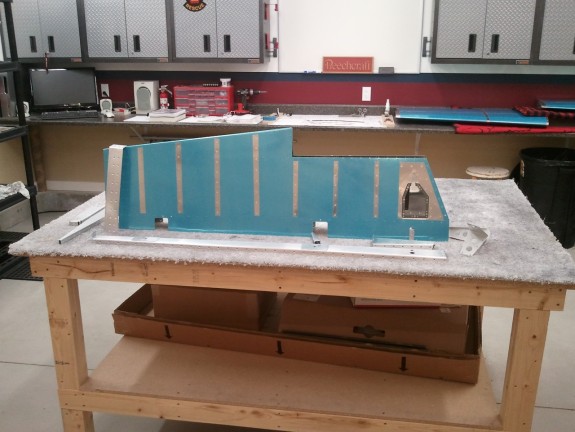

The rest of the night, I deburred, dimpled, and prepped the rest of the skeleton parts for primer. I did not dimple the skin tonight but will in the next build session.

I also added a 3/8″ hole in the E-702 spar just below the hole for the jack screw for the trim screw. I did not like the idea of the trim servo wire sharing the same hole with a piece of threaded rod. I centered the hole between the existing hole and the flange of the spar. It sits exactly centered with the existing hole as well. I think this will be a better way of routing the wire. I got the idea from another builder and have been told that no strength will be lost with a hole of this size here. Both holes will get snap bushings down the road.

It was now time to close up shop for the night and order the new trim spar.