Elevator Final Push…Almost Done!

The time came to make the final push on the elevators. This meant rolling the leading edges. This step has been one that I have NOT looked forward to for some time. You can do really nice work the entire time, and one slip up here can ruin the whole assembly. I read many ways of doing this step. I also tried different ways when it came to rolling the rudder leading edge. The saving grace is that this step does not have to be “precise” as the leading edges are hidden inside the trailing edges of the mating parts. The one catch to this is that it should not rub the interior of the trailing edge of the mating parts through the full travel of the surface. That and you still want it to look “good.”

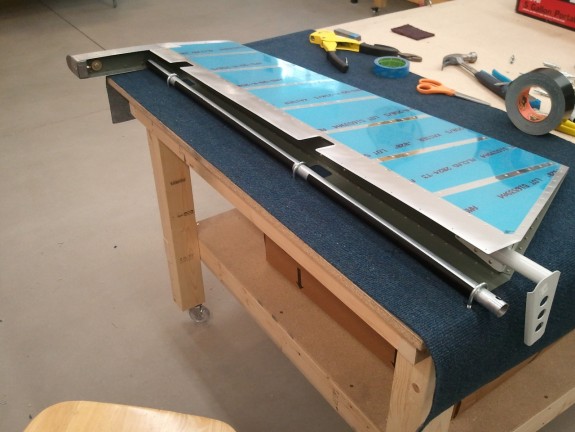

As I did with the Rudder, I took a tip from a builder over on VansAirforce.com where he used J-Bolts to hold a 3/4″ Electrical conduit to the table. This keeps the pipe close to the table and should make a nice radius. The other part of the setup is that you can drill the end of the pipe and insert a cross rod that can be used as a handle. Since you are not having to worry about holding the work to the table, you can use both hands on the handle. Supposedly you can also do all three sections of the roll at once.

So I taped the skin to the pipe using “Gorilla” brand duct tape. I think this is the same stuff the USAF calls “100mph tape” because it sticks great. I then anchored the pipe to the bench using the J-Bolts. Once I was committed, I threw my 3/8″ steel handle through the holes I drilled in the end of the conduit, and then twisted away. At first I thought…heck, this isn’t all that bad. The bends seemed to be a nice radius and all three sections rolled together nicely. This may look OK!

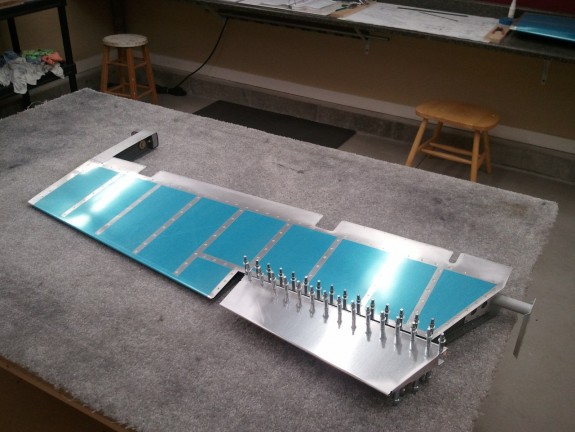

Once I removed the tape and conduit, I took a long look at the bend. The one problem I see is that I think the J-Bolt setup makes the conduit TOO effective. The radius seemed almost too tight. I massaged it as much as I could, but I learned on the rudder that too much massaging can make the problem worse in a hurry. I was reluctant to massage more than I could have for fear this may occur on the elevators. Once the bend was done, I simply pulled the skin ends together and clecod the overlap. There was some squeezing by hand to close them, but not a ton. I then match drilled, deburred, and clecod them, and then pop riveted the leading edges together. The above was the result for the left elevator. I may be hard on myself, but I wished they would have been a little more smooth in the radius. I think this again had to do with the conduit being too effective with the J-Bolts. Most that are not using the J-Bolts simply roll the edge by hand while holding the assembly to the bench. The J-Bolt eliminates the need to hold it down while rolling. In the future, if I have to do it again, I may just use a bigger diameter pipe/stick.

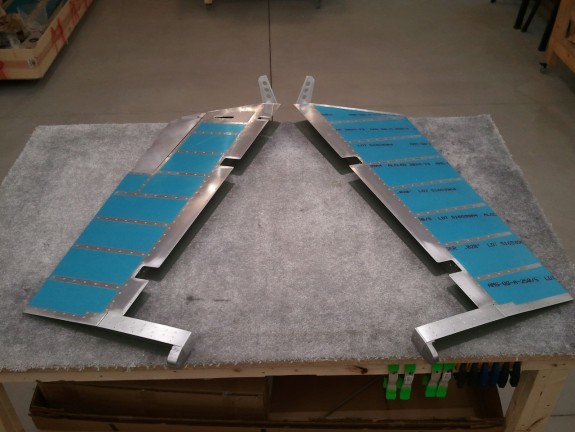

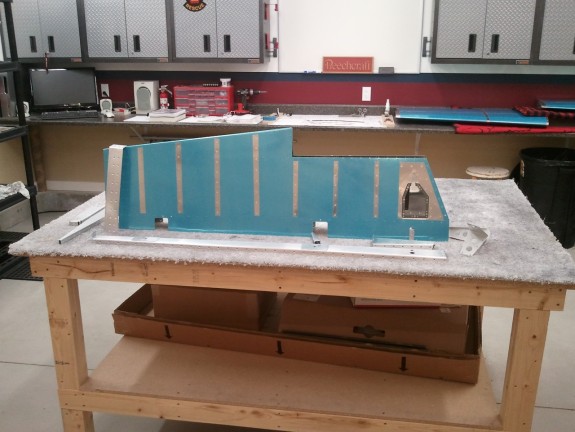

Here you can see the right elevator roll. Here you can see the tighter radius again. I tried to massage it a little more subtle, but I was still afraid of making a bigger mess than solving. As it stands, the joints at the overlap are nice and tight with no noticeable puckering. I am pretty sure they will function just fine.

At the end of the build session, I walked out of the shop with two good looking elevators. This marks the end of the MAJOR portions of the Tail Kit. This is a big milestone. What’s left then?

- Mount Elevators to Horizontal Stabilizer and trim the lower flange of the HS-603PP to clear the elevator control horns for full down travel.

- Trim the HS-601PP skin to clear the counter balance arms.

- Drill the elevator control horns for the center pivot bearing and bolt.

- Fiberglass tips for the Horizontal Stabilizer, Vertical Stabilizer, Upper Rudder, Lower Rudder, and Elevators. (Will do these when the tail is mounted to the Fuselage.)

Once items 1-3 are done, I will store these parts away for safe storage and keeping and begin the WINGS! I will also call the empennage/tail complete!